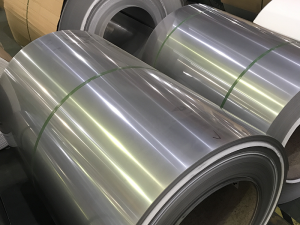

410S ʻili kila kila

wehewehe

Nā kikoʻī:

1. Kūlana: ASTM A240, JIS G4304, EN10088

2. Papa: 200series&300series&400series

3. Mānoanoa: 0.03mm - 6.0mm

4. Laulā: 8mm-600mm

5. Length: e like me ke noi a nā mea kūʻai aku

6. Ili: 2D, 2B, BA, Mirror i pau, N04, Laina lauoho, Matt pau, 6K, 8K

7.Technology: huki anu / anuanu / wela wela

Mea Hana:

| ʻAno | Papa | Papa | Mea Kimia % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | 'ē aʻe | |||

| Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

ʻIke kumu

ʻO 410s Stainless Steel Coil, me ka pale ʻana i ka corrosion maikaʻi a me ka machinability, he kila kumu nui a me ke kila mea hana.ʻO 410S keʻano o ke kila e hiki ai ke hoʻonui i ka paleʻana i ke kino a me keʻano o ke kila 410. ʻO 410S he kila ikaika kiʻekiʻe e hiki ai ke hoʻonui i ka paleʻana o ke kila 410.Hoʻohana ʻia ia no nā ʻāpana turbine a me nā ʻāpana wela kiʻekiʻe.

• Nā kikoʻī: AISI 410s, ASTM 410s

• Hoʻopau: Baʻilikai, 2bʻilikai, No.1 (ʻili keʻokeʻo), 2Dʻili, No.4 (hau), HL (wire kaha kiʻi), 8Kʻili he maikaʻi ka maikaʻi o kaʻili.

• E pili ana nā tolerances Mill ma ka mānoanoa a me ka palahalaha. E kelepona iā JM Steel inā makemake ʻoe i nā nui kikoʻī a i ʻole ke kuhikuhi ʻana i ka palaoa.

410S ʻenehana mīkini maʻamau

1D -- Loaʻa i ka ʻili ke ʻano granular pau ʻole, ʻike ʻia hoʻi ʻo ka ʻili noe.

ʻenehana hana ʻenehana: ʻōwili wela + pana hoʻopiʻi peening pickling + ʻōwili anuanu + pickling annealing.

2D - He kala keʻokeʻo keʻokeʻo iki.

ʻenehana hana ʻenehana: ʻōwili wela + pana hoʻopiʻi peening pickling + ʻōwili anuanu + pickling annealing.

2B -- Kālā keʻokeʻo me ka ʻōlinolino maikaʻi a me ka palahalaha ma mua o ka ʻili 2D.

ʻO ka ʻenehana hana: ʻōwili wela + hoʻoheheʻe ʻana i ka pana peening pickling + ʻōwili anuanu + ʻaila annealing + hoʻopaʻa ʻana a me ka ʻōwili ʻana.

Ba - ʻOi aku ka ʻōlinolino o ka ʻili, kiʻekiʻe ka nānā ʻana, e like me ka ʻili aniani.

ʻenehana hana ʻenehana: ʻōwili wela + hoʻoheheʻe ʻana i ka pana peening pickling + ʻōwili anuanu + pickling annealing + hoʻoliʻiliʻi i luna + hoʻopaʻa a me ka ʻōwili ʻana.

No.3 -- Olino maikai, ili palaoa kopa.

ʻenehana hana: polishing a me ka tempering rolling no 2D a i ʻole 2B me 100 ~ 120 mau mea abrasive (JIS R6002).

No.4 -- Nani maikaʻi, nā laina maikaʻi ma ka ʻili.

Ke kaʻina hana: polishing a me ka tempering rolling no 2D a i ʻole 2B me 150 ~ 180 mau mea abrasive (JIS R6002).

HL -- Kahinahinahina me ka lauoho lauoho.

ʻenehana hana: ʻO nā huahana 2D a i ʻole nā huahana 2B me ka granularity kūpono o nā mea abrasive no ka hoʻoliʻi ʻana i ka ʻili he palaoa abrasive mau.

MIRRO -- Specular.

ʻenehana kaʻina hana: nā huahana 2D a i ʻole nā huahana 2B me ka granularity kūpono o ka mea wili e wili a hoʻoliʻi i ka hopena aniani.